3D forming center is developed to process raw materials like coils, wire rods, and particles into components with complex spatial structures, such as bended steel bars, 3D printed cement and decoration materials, and customized welded metal components. It is ideal for producing customized components in architectural design projects that are non-standard and elaborately designed in small quantities.

Powered by robot software and hardware technology, this center enables efficient, accurate, and continuous automated production on site, eliminating the repetitive and tedious manual work and reducing the production cost of 3D components.

In the construction process, the plates, section bars, pipes, and wires are delivered to the construction sites in standard sizes. However, due to the complex construction conditions, these materials often need to be tailored to the appropriate size for installation on site before being moved immediately to the desired position.

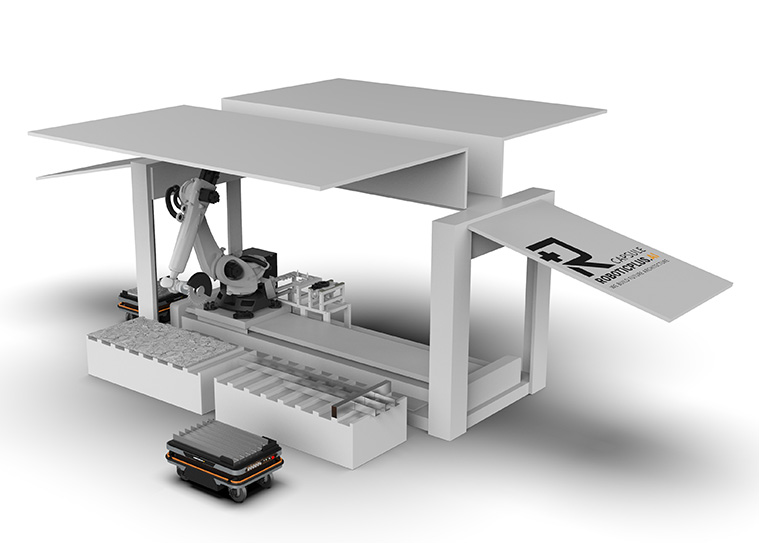

The subtractive manufacturing and material transport system integrates the software and hardware required to meet the processing needs of multiple materials. It is equipped with APE, the mobile chassis from RoboticPlus.AI, to facilitate material transportation. This means it can transport stones, metal, or other building and decoration materials after cutting, grooving, drilling, etc., enabling 1 to N automatic production.

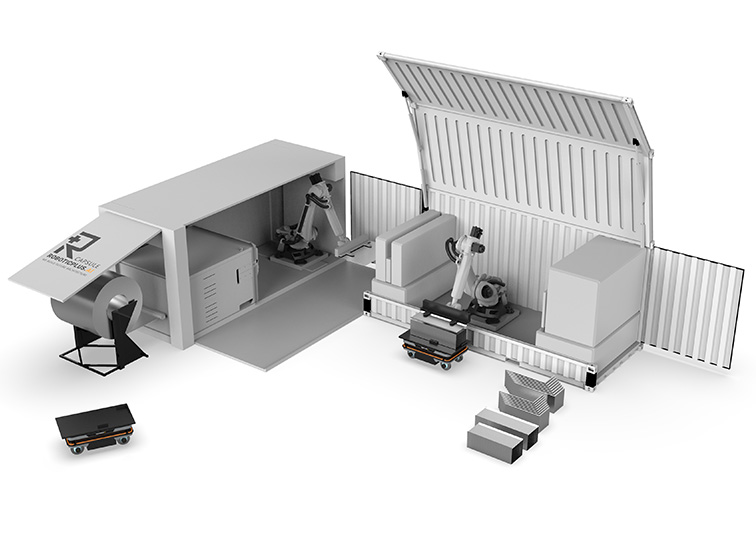

The clustered flexible production line is built for component production and processing applications that involve large quantities, complicated processes, and multiple techniques. It integrates dedicated CNC machines, industrial robots, and other automation equipment into multiple production modules, transports them to the construction sites, and then assembles them into intelligent, flexible production lines on site through quick connection and deployment between modules.

Under the control of the ROBIM cloud platform, the robot can connect and coordinate with various automation equipment, allowing for an efficient Plug and Play operation. This helps improve automation productivity and promote the transformation to intelligent construction.