News

cutting-edge technology

Intelligent construction lab results

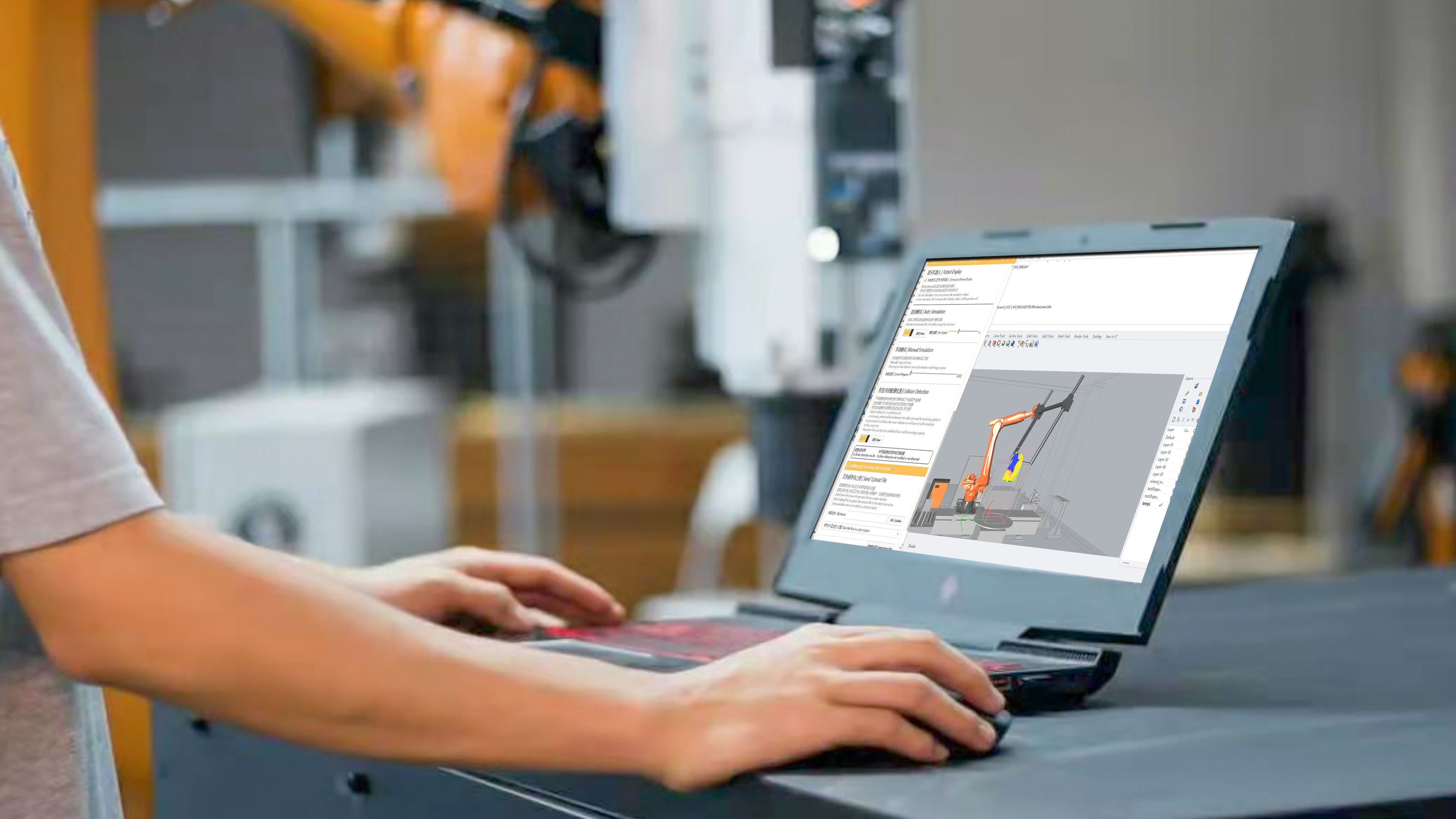

Under the guidance of the national 14th Five-Year Plan policy, colleges and universities across the country have gradually set up intelligent construction majors,

and in recent years, Dajie has actively participated in the construction of domestic university laboratories, providing them with advanced multi-process and multi-material

laboratory hardware and software solutions, and with the help of our industrial experience, and colleges and universities have gradually formed a set of composite talent

training programs for the new discipline of intelligent construction.

ntelligent Construction Lab X Compound mobile robot

On the basis of the construction of the existing intelligent laboratory, Roboticplus.AI actively responds to the important guidance on the scientific research

construction of colleges and universities in the Guiding Opinions on Promoting the Coordinated Development of Intelligent Construction and Building

Industrialization of the Ministry of Housing and Urban-Rural Development, as well as Academician Ding Lieyun's forward-looking requirements for intelligent

construction as a new engineering major . We have created a more systematic, integrated, open source, flexible intelligent laboratory equipment to help the

training of interdisciplinary talents, a variety of frontier exploration, and promote the intelligent upgrading of the industry.

In recent years, the cutting-edge building robot laboratory represented by ETH has made a lot of attempts to expand the application possibility of robots, among

which the most representative result is the composite mobile robot, which greatly expands the application scenario of intelligent robots. Considering that it may

have the great potential to further promote the subject upgrading and industrial transformation of Chinese universities, compound mobile robots are gradually

entering the line of sight of intelligent laboratories in domestic universities.

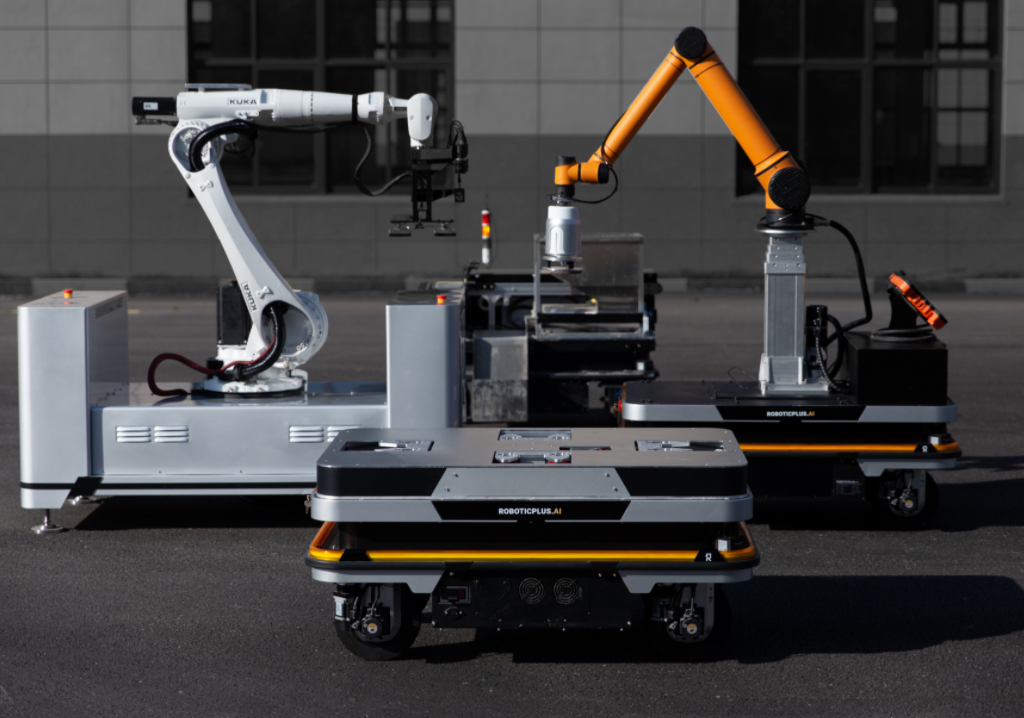

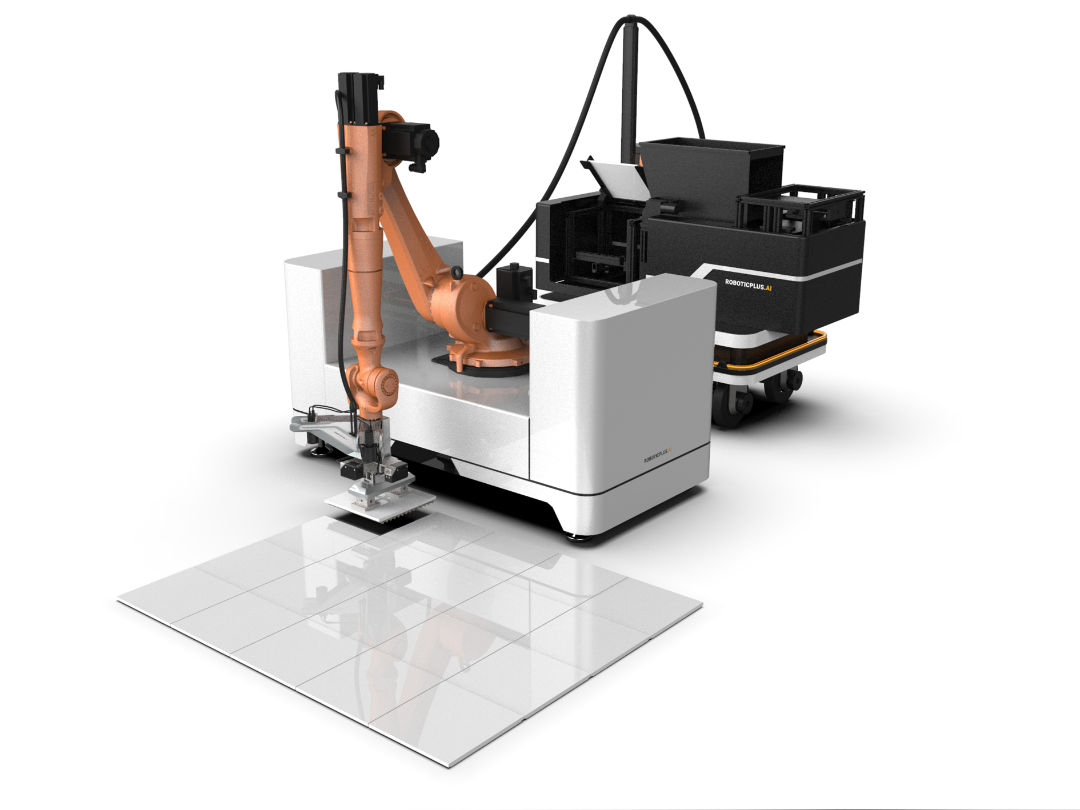

Roboticplus.AI has been deeply engaged in the field of intelligent construction for many years, and in 2020, it has launched a robot adaptation product with

a leading level in the construction robot industry - intelligent mobile chassis, and eventually evolved into a composite mobile robot with man-machine integration,

intelligent perception, and autonomous decision-making capabilities in practice. Based on the actual production environment of the construction industry,

we hope to expand the research application scenarios and practical scale with the technical advantages of highly integrated "brain, eye and hands".

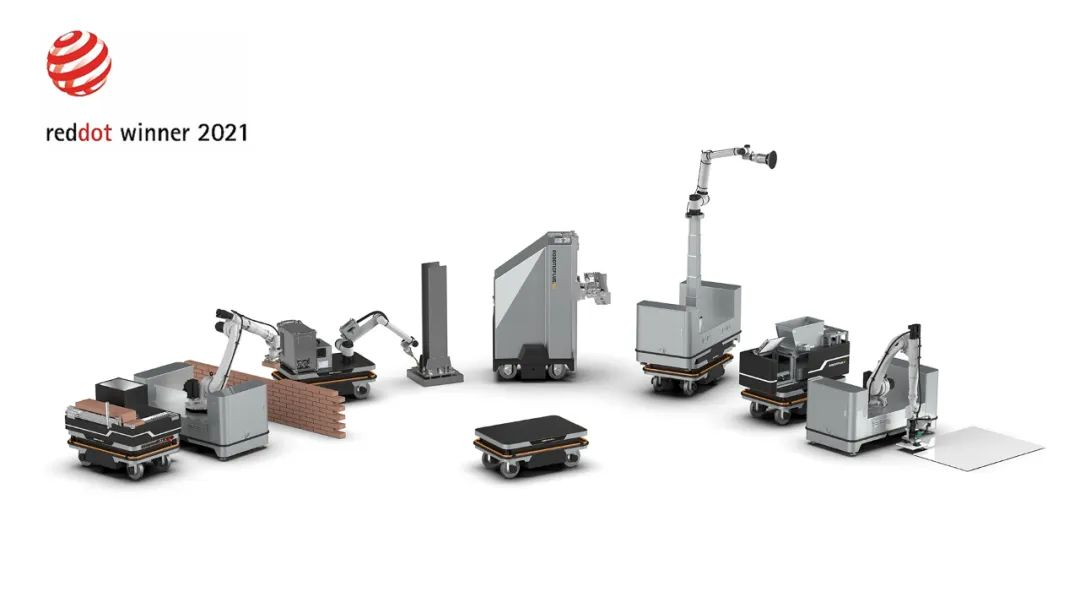

Roboticplus.AI Composite mobile Robot won the Red Dot Award in 2021

Core technology advantage

Easy to use, low learning threshold

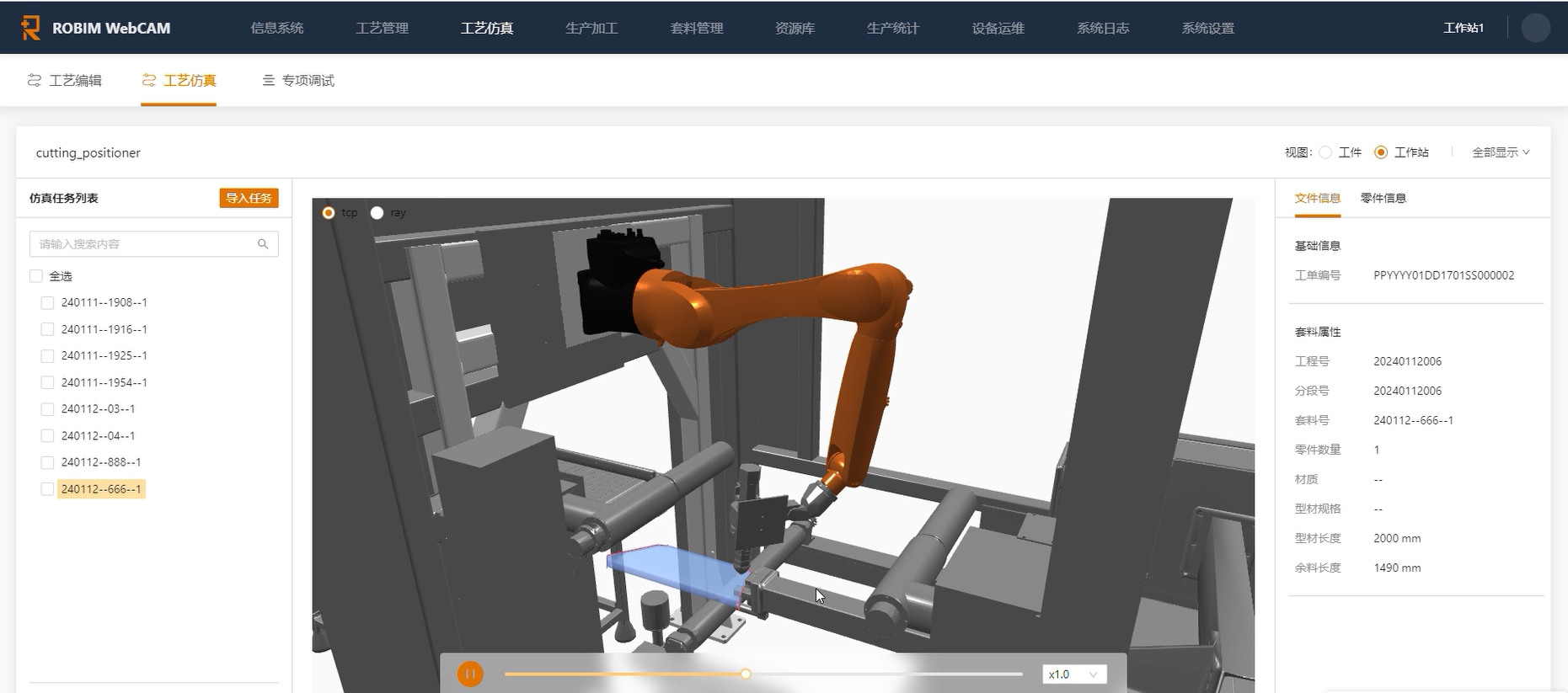

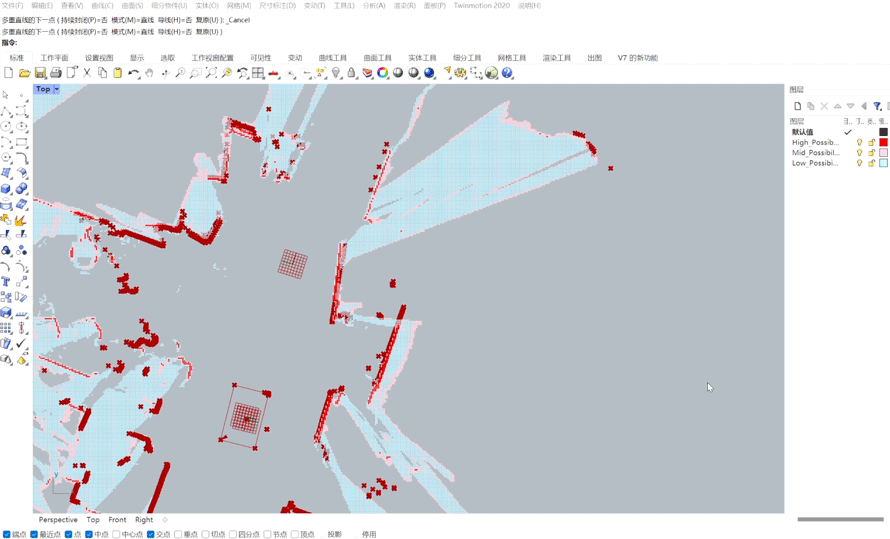

Combined with Dajie self-developed RoBIM software package, the composite mobile robot integrates all control and demonstration functions in Rhino+Grasshopper

platform to achieve digital twin, providing no code programming for teachers and students of architecture and civil engineering, greatly reducing the use threshold

and learning cost, so that students will be more energy in the research content rather than the use of tools.

Real-time control with Grasshopper process package

In addition to the Grasshopper platform programming control, the chassis movement can also be easily remote controlled through the handle.

Handle remote control chassis

2.Convenient deployment and adaptive environment

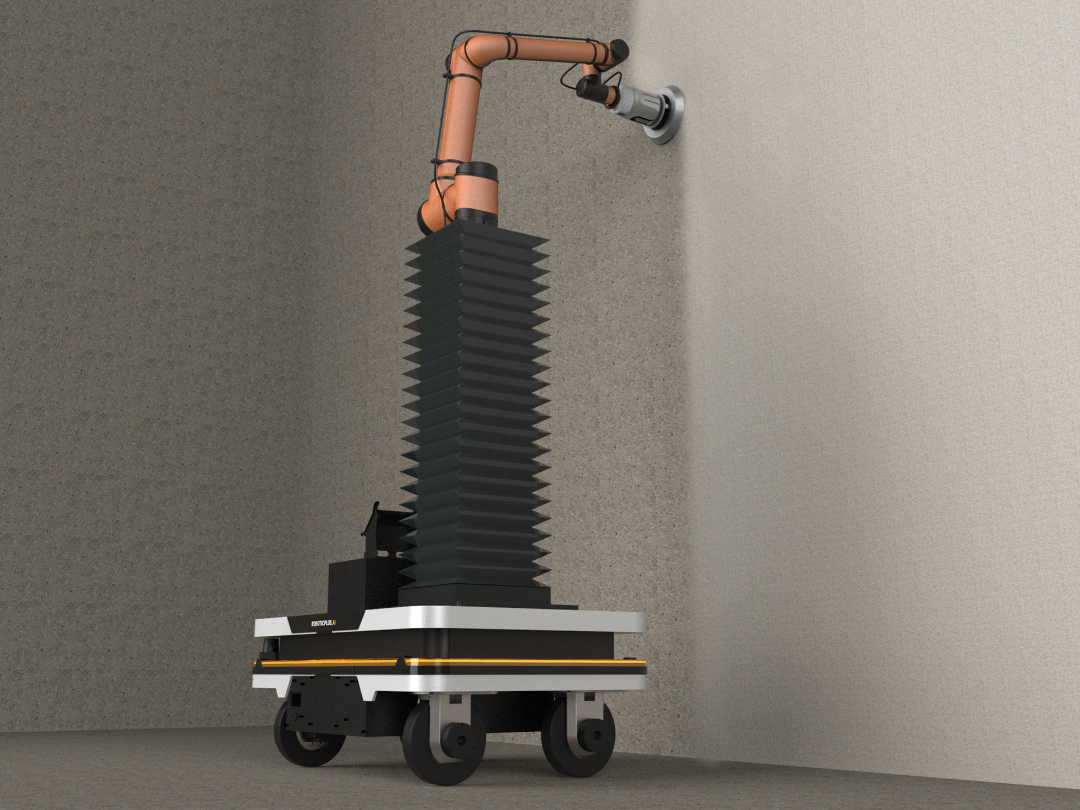

With independent positioning, mapping, and navigation capabilities, no scenario modification is required to achieve rapid deployment in various environments.

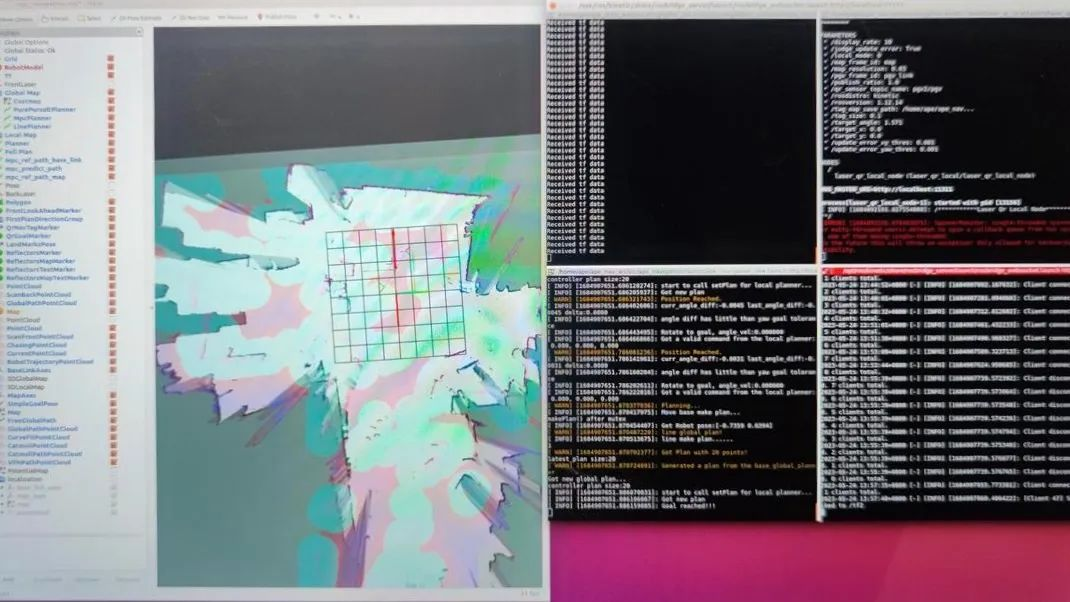

Navigation and positioning based on ROS system, SLAM simultaneous positioning and mapping. In the unknown environment, the robot moves to determine its

own positioning and completes the establishment of the incremental map. With 2D and 3D SLAM radar, stable output of high-quality point clouds, ensure ±2cm

ranging accuracy, even in outdoor high vibration, rain and fog weather and other harsh environment can operate normally.

3.Provide interface, can be customized development

The operating system is based on the open source ROS platform, adopts a standardized development interface, and is highly scalable, which can support the

current mainstream robot arm and various tool heads and a variety of sensor collaborative vision systems. At the same time, the software and hardware integration

services provided by Dajie can be rapidly developed according to the application scenario, greatly shorten the development cycle, and meet the constantly updated

scientific research needs of colleges and universities.

4.Multiple guarantees, safety

Relying on the powerful navigation and positioning system, it can achieve accurate automatic obstacle avoidance and provide security. In addition, anti-collision

strips are installed around the chassis, which can trigger induction and automatically power off once a collision occurs. Manual emergency stop can also be

realized by shooting the body emergency stop switch and the emergency stop remote control button, so as to cope with emergencies.

Due to school measures, multi-target training

Facing the opportunities and challenges of new engineering construction in the digital age, it is of great significance to train a large number of high-level composite

engineering talents for the transformation and upgrading of the industry. At the same time, due to the different positioning and disciplinary advantages of colleges

and universities, composite mobile robots can train students' ability to "master algorithms, drive devices, and solve engineering problems" with the help of their

man-machine integration and multi-scene application advantages.

Training of industrial talents

Based on the basic functions of composite mobile robots, Roboticplus.AI has expanded professional application programs such as welding, tiling, cutting, grinding,

spraying, etc., and relies on the self-developed RoBIM cloud platform to help students master the operating process of robot equipment from intelligent identification,

independent decision-making to accurate construction, bidding farewell to the cumbersome operation of software and stepping into the era of one-click.

2.Training of innovative talents

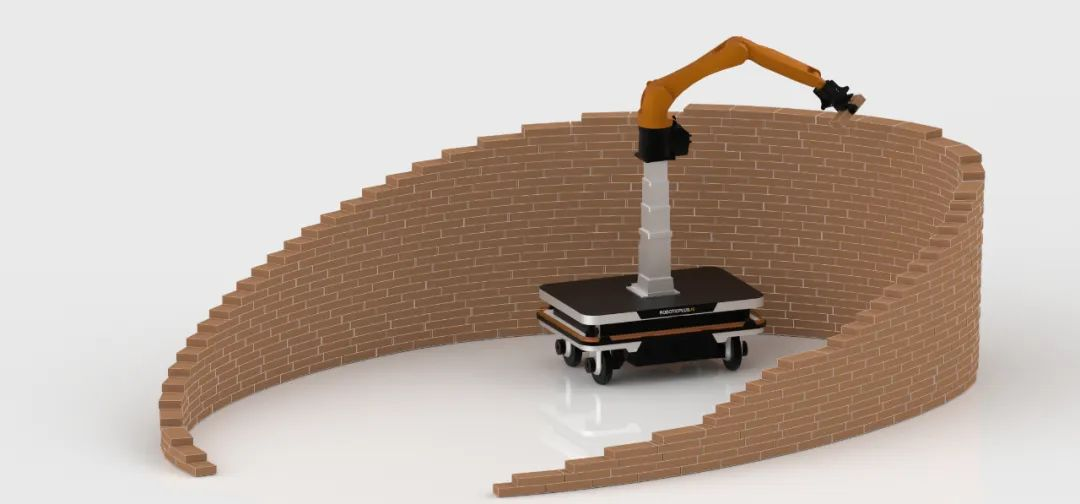

In the context of traditional construction technology, the assembly method of building materials is often greatly limited, and common industrial robots are

difficult to break through the inherent construction scale due to the fixed installation method. The use of composite mobile robots can complete the construction

of larger scale and more complex forms on the basis of the digitalization and customization already achieved by robots, so as to help teachers and students of

architecture and civil engineering colleges and universities to constantly explore the boundaries of disciplines in today's highly informationized era.

a. Establish application research

Transport masonry is a common research direction in the field of intelligent construction. The composite robot equipped with a mobile chassis can complete

complex construction tasks with high degree of personalization by means of flexible movement characteristics, and the error is controlled at the millimeter

level by combining the stereo RGB phase unit and computer vision algorithm. By replacing specific tool heads, masonry work with a variety of unconventional

materials (such as irregular wood, stone, foam, etc.) can also be satisfied. At the same time, the installation of the lifting device can break through the limitation

of the processing height, and provide the possibility for the practical project of studying the new construction method.

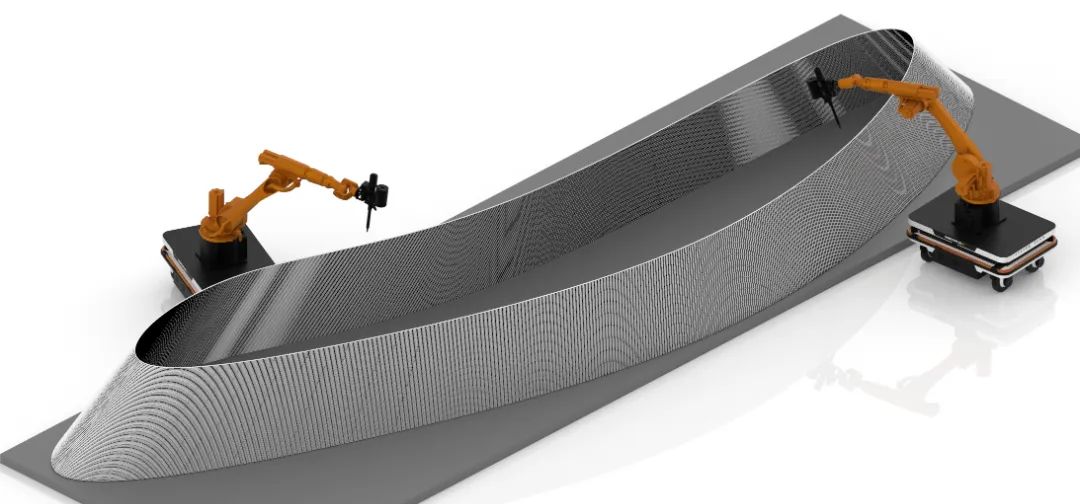

b. Application research of dual-machine collaboration

By controlling two composite mobile robots to work together, processing tasks of larger scale and more complex shape can be completed, such as the construction

of mutually dependent structures, large-scale 3D printing, etc., and autonomous operations under dual-machine collaboration can be better studied.

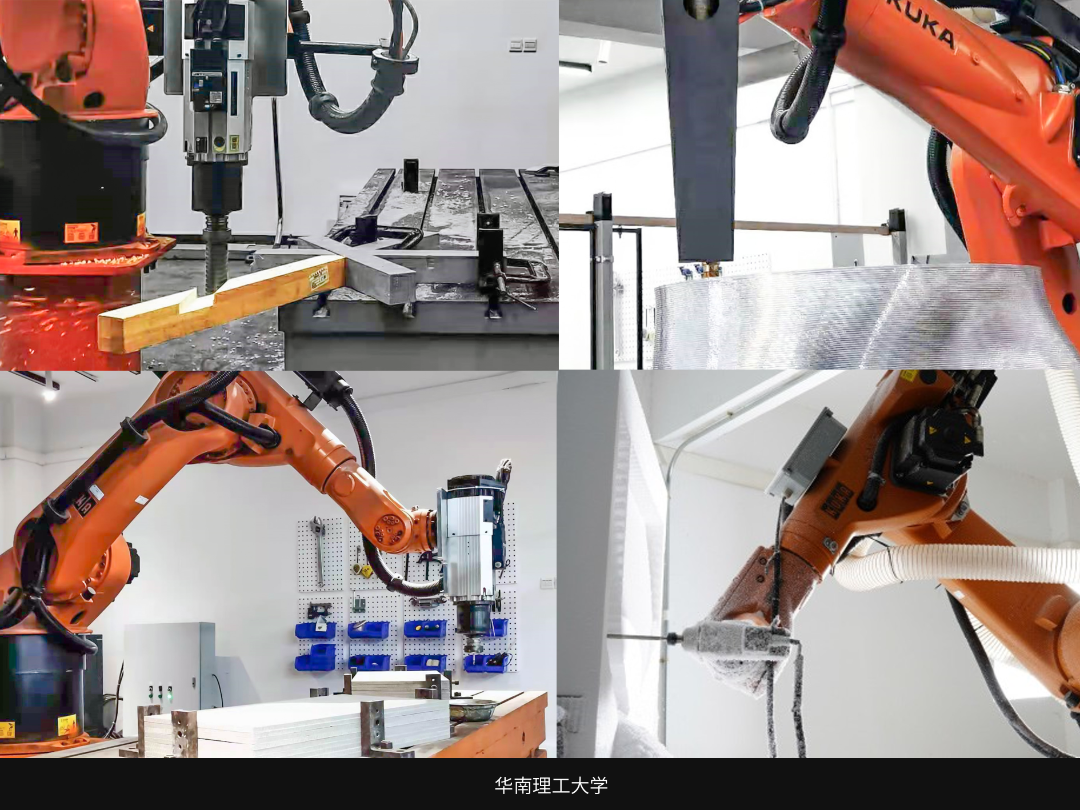

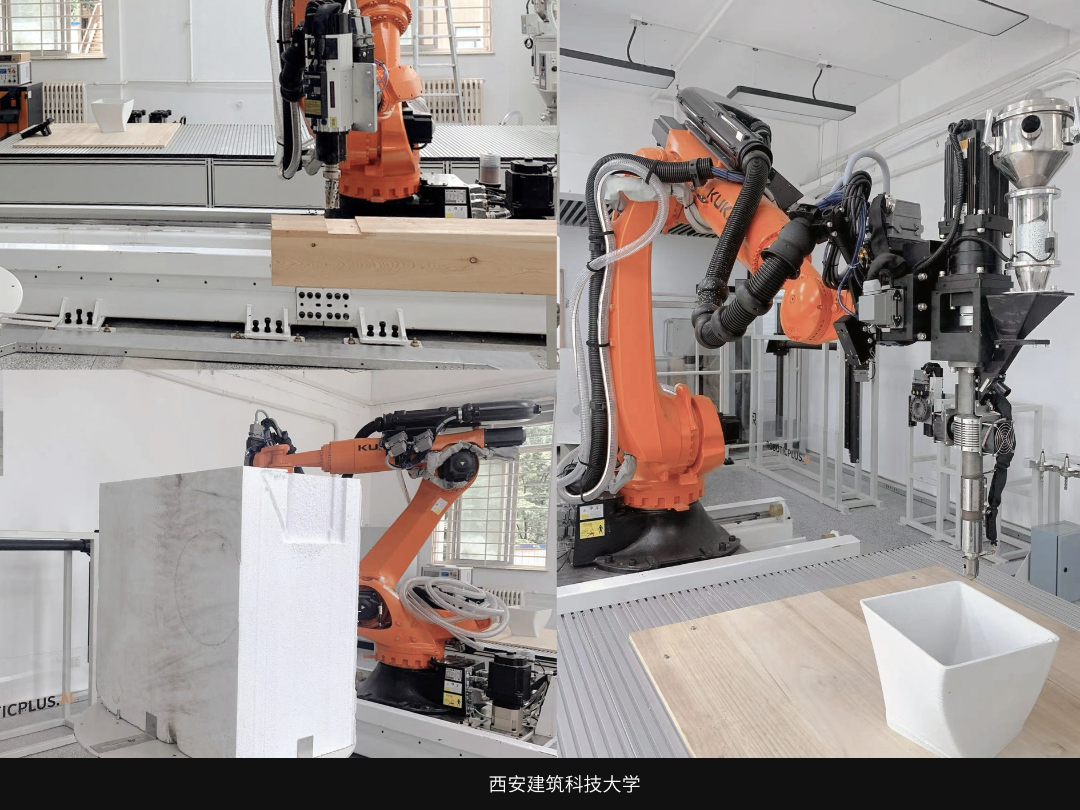

University case sharing

Tianjin University

In order to realize the automatic construction of unconventional materials in complex scenes, Tianjin University has conducted in-depth research on the integration of

digital design and construction, and completed the palletizing test through Dajie composite mobile robot. In the future, it will continue to carry out digital construction

courses with the help of it, realize the automatic palletizing of parametric walls in indoor venues, and further study more construction methods.

2.Feng Chia University, Taiwan

In order to solve the problem of the aging of construction workers, Fengjia University in Taiwan has prepared to build a ROSO laboratory to study the automatic

construction scheme of the site. By combining the composite robot and the lifting system, the limitation of the construction area is overcome to the maximum extent,

and the tasks with large area and high repeatability can be quickly completed. After the team's secondary development, it can now be applied to the site to meet a

variety of construction needs.