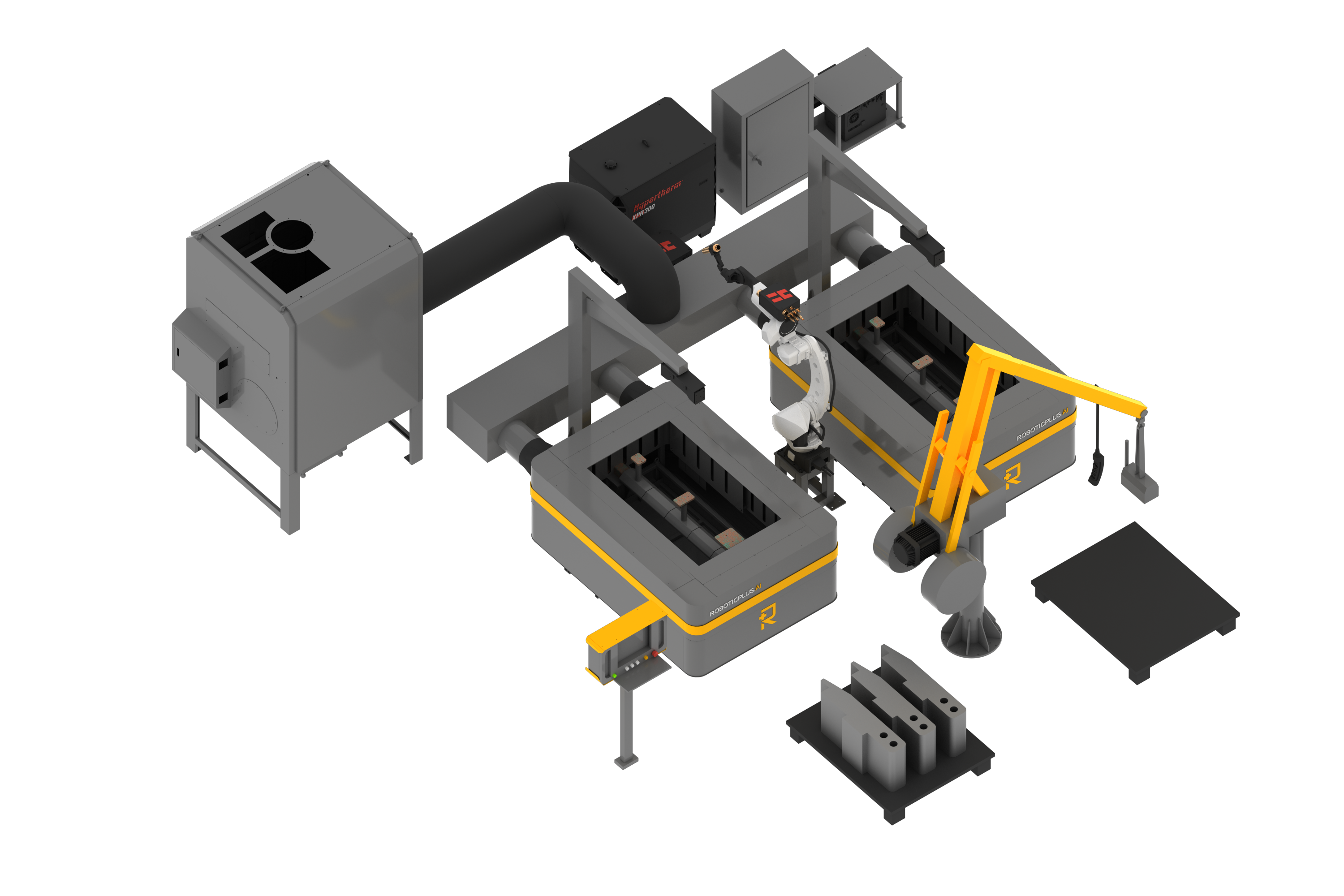

Application:

Small-sized workpieces requiring beveling, such as steel structure beams and columns, hydraulic brackets, and construction machinery components.

Features:

![]() Achieves high-precision visual positioning in just 15 seconds.

Achieves high-precision visual positioning in just 15 seconds.

![]() Offers high flexibility, suitable for processing tasks on variously shaped workpieces.

Offers high flexibility, suitable for processing tasks on variously shaped workpieces.

![]() Compact layout; a single worktable can support multiple workpiece cutting simultaneously.

Compact layout; a single worktable can support multiple workpiece cutting simultaneously.

![]() User-friendly graphical software interface, ensuring ease of operation.

User-friendly graphical software interface, ensuring ease of operation.

Application:

Tailored to meet the beveling needs of the mining equipment manufacturing sector, including vital machinery such as scraper conveyors, hydraulic supports, roadheaders, and associated equipment.

Features:

![]() Fully automated processes including loading, bevel cutting, grinding, and discharging.

Fully automated processes including loading, bevel cutting, grinding, and discharging.

![]() High-precision vision system automatically corrects incoming material deviation to ensure processing quality.

High-precision vision system automatically corrects incoming material deviation to ensure processing quality.

![]() Automatic matching of process parameters and autonomous robot path planning.

Automatic matching of process parameters and autonomous robot path planning.

![]() Advanced software capable of meeting customized production requirements.

Advanced software capable of meeting customized production requirements.

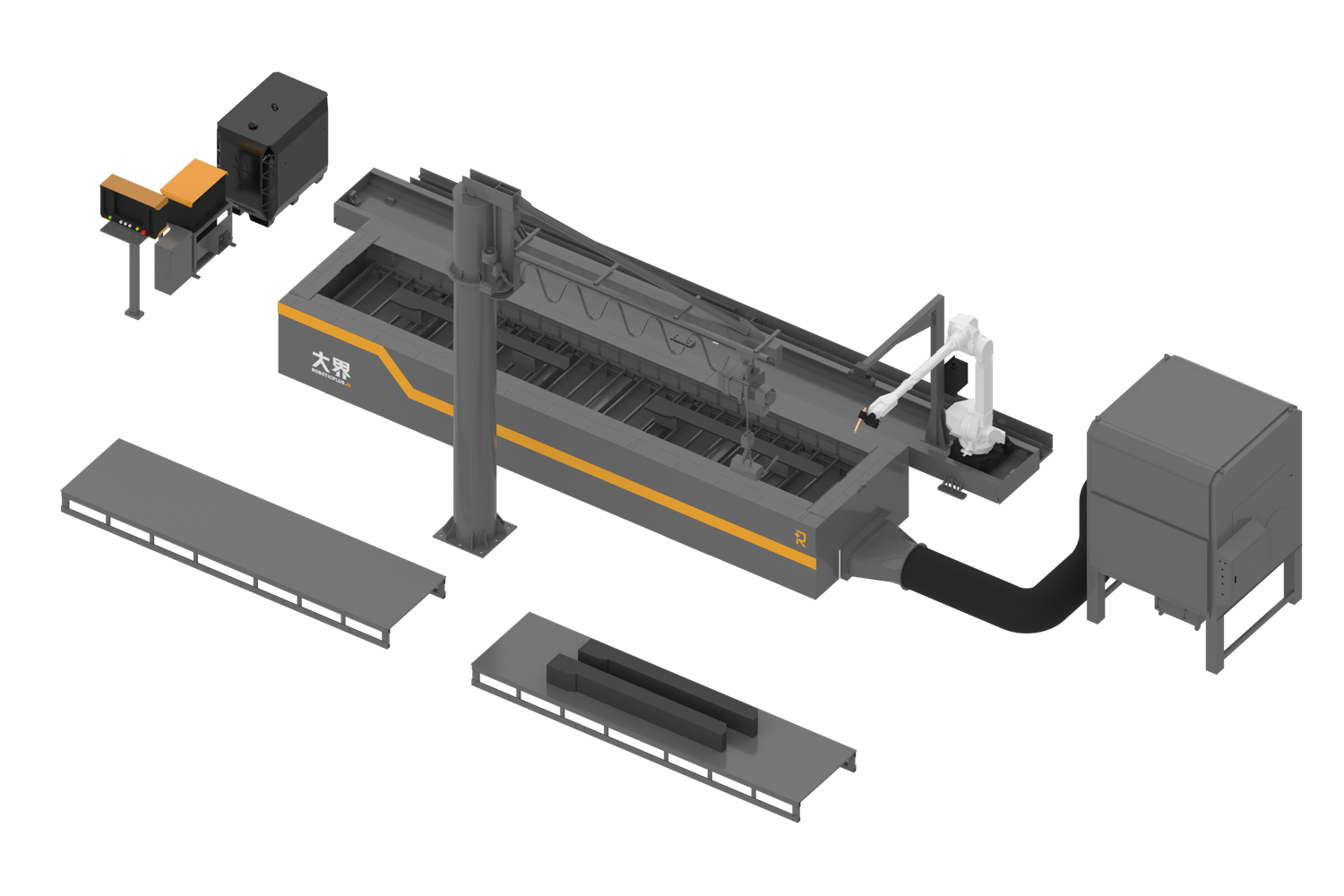

Application:

Ideal for beveling medium and large-sized workpieces in industries such as coal mining, construction machinery, shipbuilding, and more.

Features:

![]() Accurately locates the workpiece position through line laser scanning and reconstructs its outer contour.

Accurately locates the workpiece position through line laser scanning and reconstructs its outer contour.

![]() Capable of completing complex bevel cutting tasks for large-sized workpieces through seventh-axis linkage.

Capable of completing complex bevel cutting tasks for large-sized workpieces through seventh-axis linkage.

![]() Processing workpiece range: 200mm x 200mm to 6000mm x 800mm.

Processing workpiece range: 200mm x 200mm to 6000mm x 800mm.

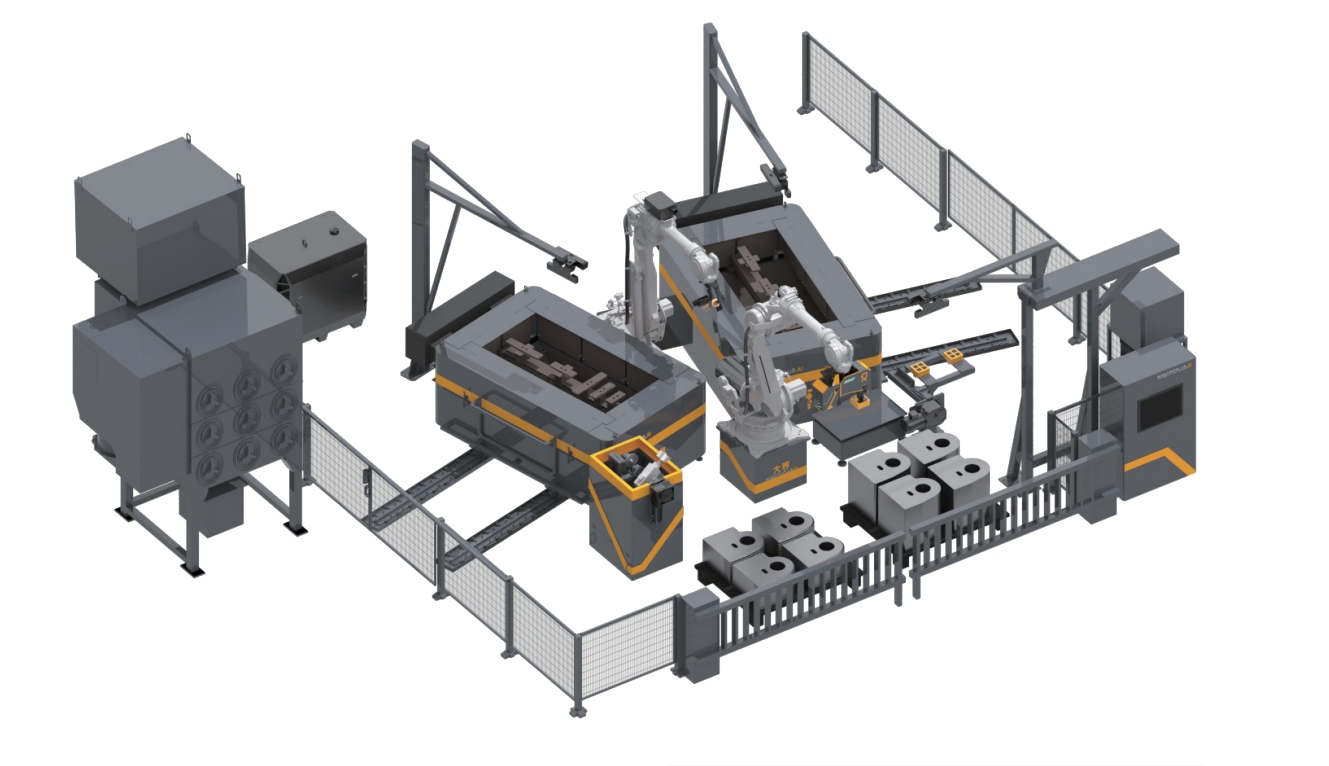

Application:

Suitable for medium-sized beveled workpieces for coal mining machinery and construction machinery.

Features:

![]() With RobimCut and advanced algorithms, it automates importing drawings and 3D models, generates bevel parameters, plans process paths, and creates robot work programs with a single click.

With RobimCut and advanced algorithms, it automates importing drawings and 3D models, generates bevel parameters, plans process paths, and creates robot work programs with a single click.

![]() Vision algorithms and multi-sensor fusion ensure precise workpiece handling throughout loading, cutting, grinding, and unloading.

Vision algorithms and multi-sensor fusion ensure precise workpiece handling throughout loading, cutting, grinding, and unloading.

![]() Efficiency is increased by 80% through dual robot collaboration during cutting.

Efficiency is increased by 80% through dual robot collaboration during cutting.

![]() Automatic process adjustments during grinding enable seamless transition to welding without manual intervention.

Automatic process adjustments during grinding enable seamless transition to welding without manual intervention.

![]() Integration with MES systems and AGVs via open ports enhances overall production efficiency.

Integration with MES systems and AGVs via open ports enhances overall production efficiency.

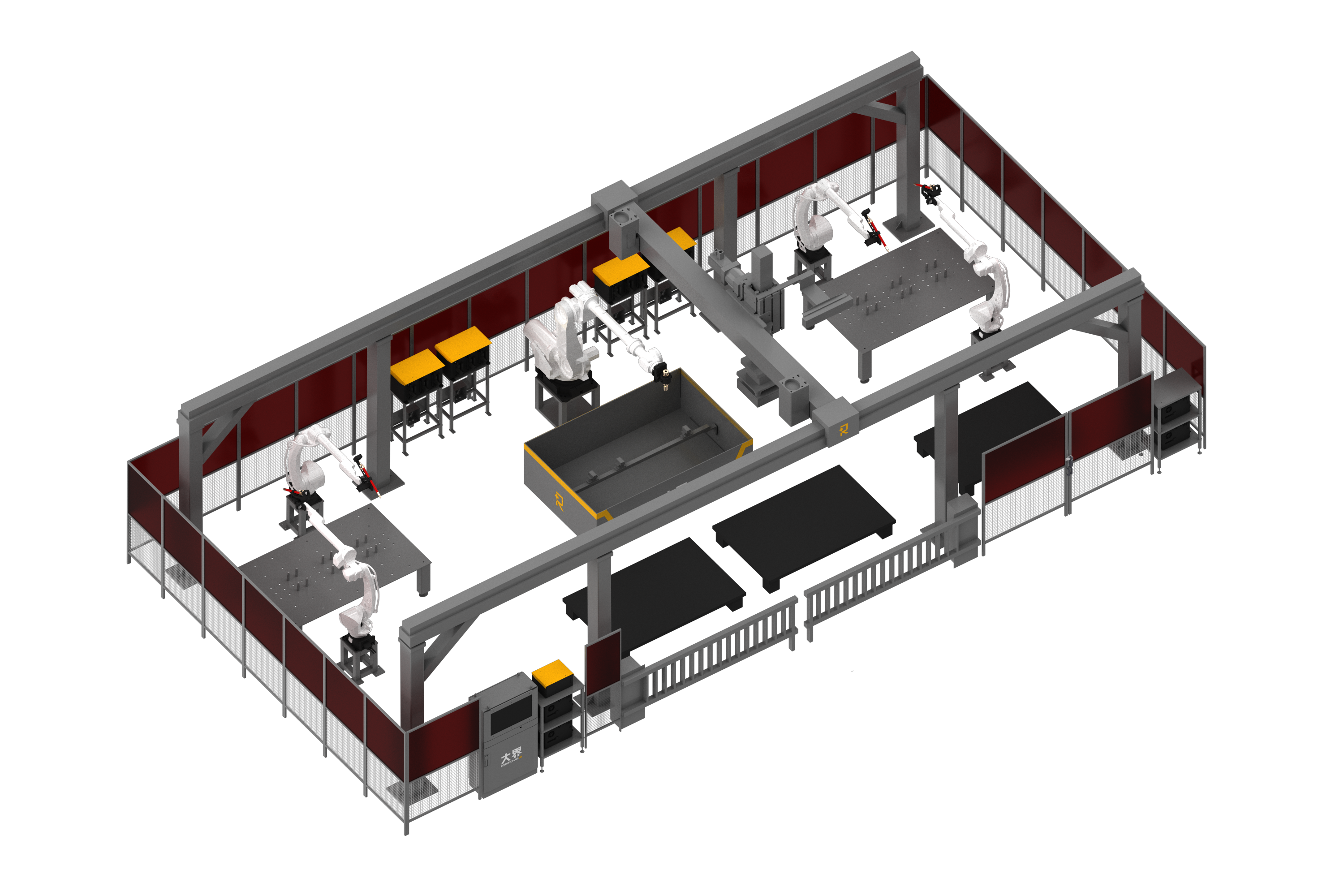

Application:

Tailored for profile cutting requirements in shipbuilding, offshore, construction, bridge construction, and other related industries.

Features:

![]() Compatible with design software such as Tribon, AVEVA, CATIA, SPD, TEKLA, CAD, and others.

Compatible with design software such as Tribon, AVEVA, CATIA, SPD, TEKLA, CAD, and others.

![]() Macro library enables secondary development and limitless expansion to accommodate user customization requirements.

Macro library enables secondary development and limitless expansion to accommodate user customization requirements.

![]() Autonomous path planning and motion simulation of robot cutting eliminate the need for manual programming, enhancing production efficiency.

Autonomous path planning and motion simulation of robot cutting eliminate the need for manual programming, enhancing production efficiency.

![]() Intelligent algorithms ensure optimal process parameter matching for precise cutting.

Intelligent algorithms ensure optimal process parameter matching for precise cutting.

![]() Utilizes cutting-edge nesting algorithms to enhance material utilization and cost savings.

Utilizes cutting-edge nesting algorithms to enhance material utilization and cost savings.