News

cutting-edge technology

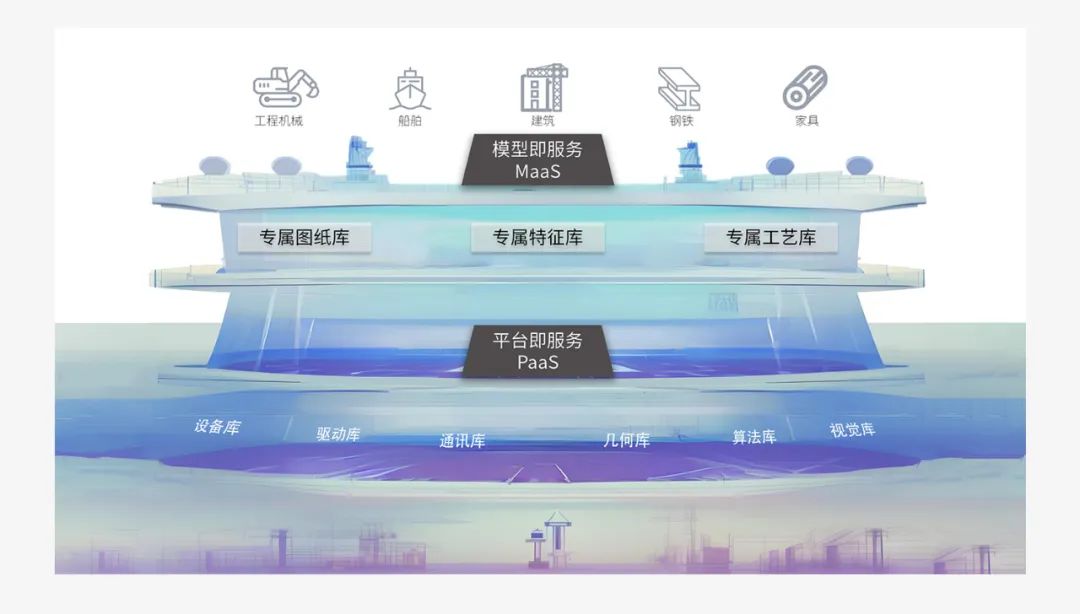

RoBIM Cloud, an intelligent robotics flexible production platform, is designed to assist manufacturing industry professionals in rapidly deploying robotics solutions. Drawing from extensive experience in construction, shipbuilding, and heavy industries, RoboticPlus.AI has integrated "algorithm+data+process" modeling capabilities into the RoBIM Cloud platform.

Addressing the industry's existing challenges of inflexibility and lack of intelligence, RoBIM Cloud offers three core technology bases. By leveraging geometric algorithms, numerical optimization methods, and AI technology, we provide a low-code, programming-free cloud platform for seamless import and instant production of large-scale drawings and models.

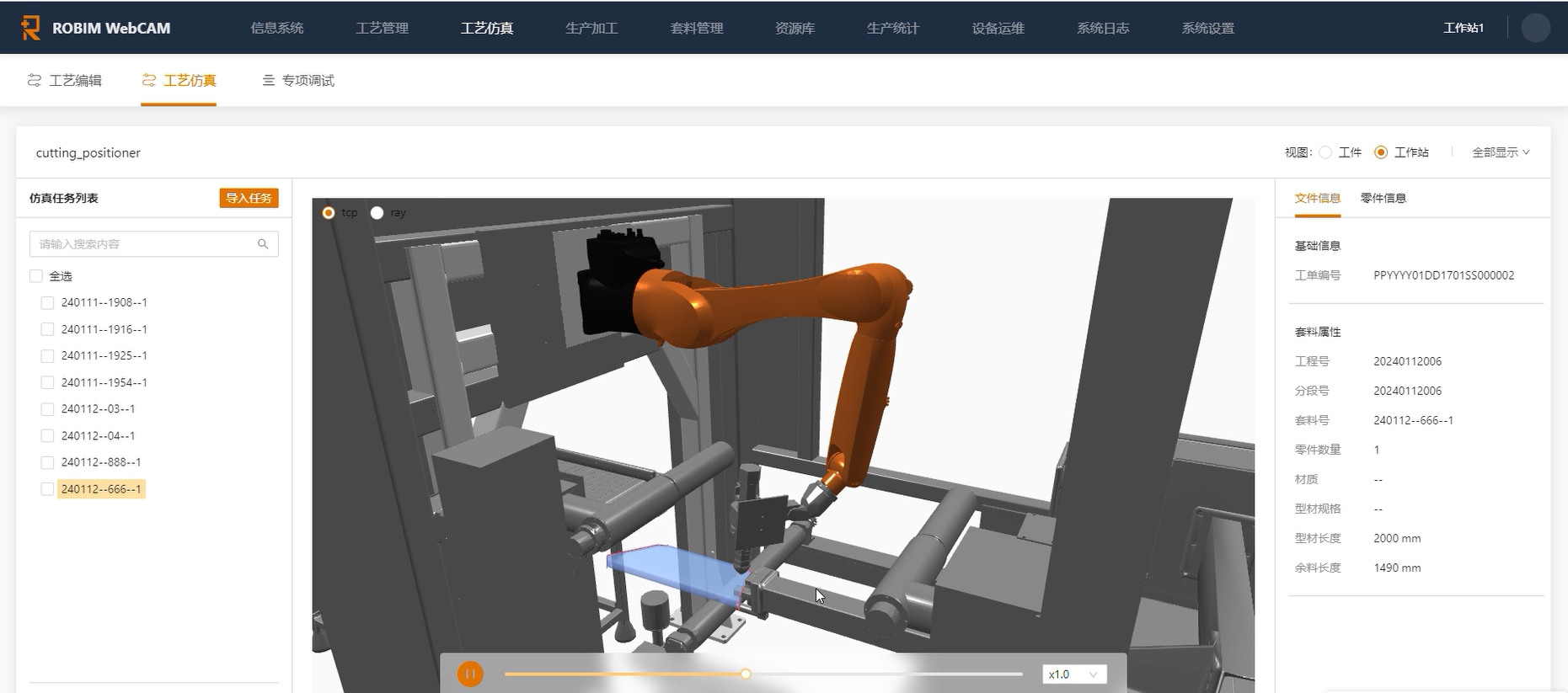

Offering a comprehensive simulation environment, the Digital Twin enables users to simulate, analyze, and optimize production processes, enhancing design efficiency.

Supporting various file formats, including DXF, GEN, IFC, and STEP, this module intelligently analyzes drawings to facilitate flexible production and ensure compatibility with diverse workpieces.

With a continuously updated process database, this module enables self-decision and self-optimization of processes, ensuring lean production and eliminating manual adjustments.

In addition to providing basic industrial robot flexible production capabilities, this module offers customized production models tailored to customer-specific requirements, promoting intelligent model-driven flexible production.

Enables planning and strategy-building for digitalized smart factories.

Facilitates comprehensive display of hardware products and assists technicians in better understanding hardware performance.

Supports the development, evaluation, and presentation of solutions to customers in a more intuitive manner.

Provides algorithm testing and simulation environments to facilitate robotics and automation research projects.