News

cutting-edge technology

The Hong Kong SAR Government's Northern Metro Area Development Strategy advances the city's growth by addressing housing needs and refining urban planning through extensive residential construction. Meanwhile, the "Simple Public Housing" project underscores the potential of modular construction. However, automation and intelligence in construction lag behind.

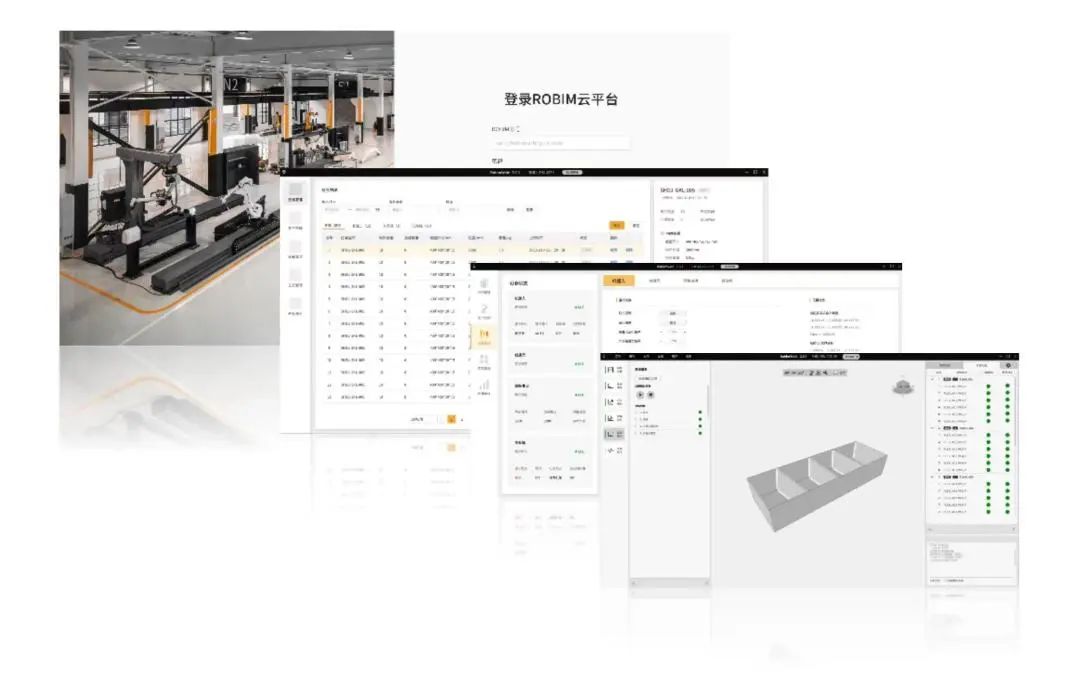

Enter RoboticPlus.AI, offering a solution with its self-developed intelligent welding system and laser vision algorithms. This streamlines modular steel structure production, enabling efficient, high-quality, and cost-effective welding.

1.Enhanced Production Process and Intelligent Welding

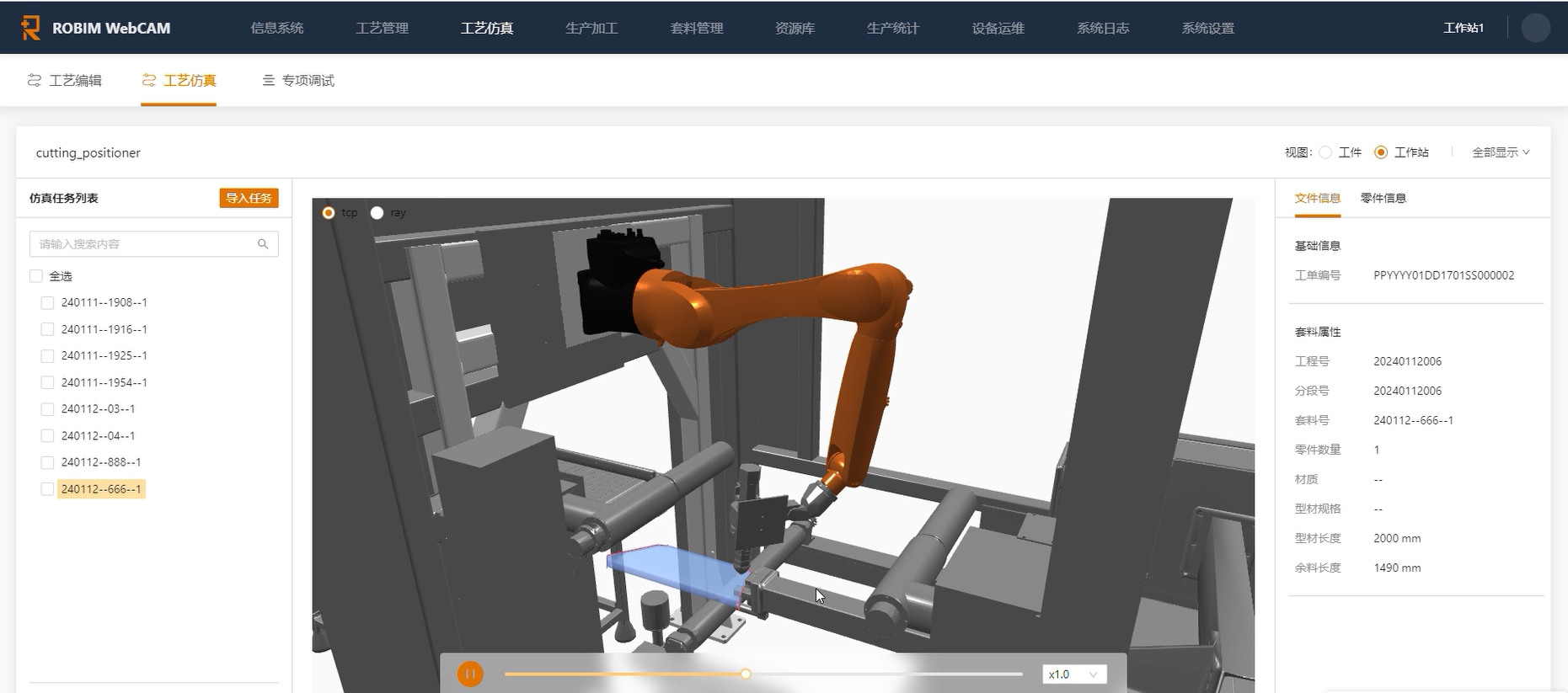

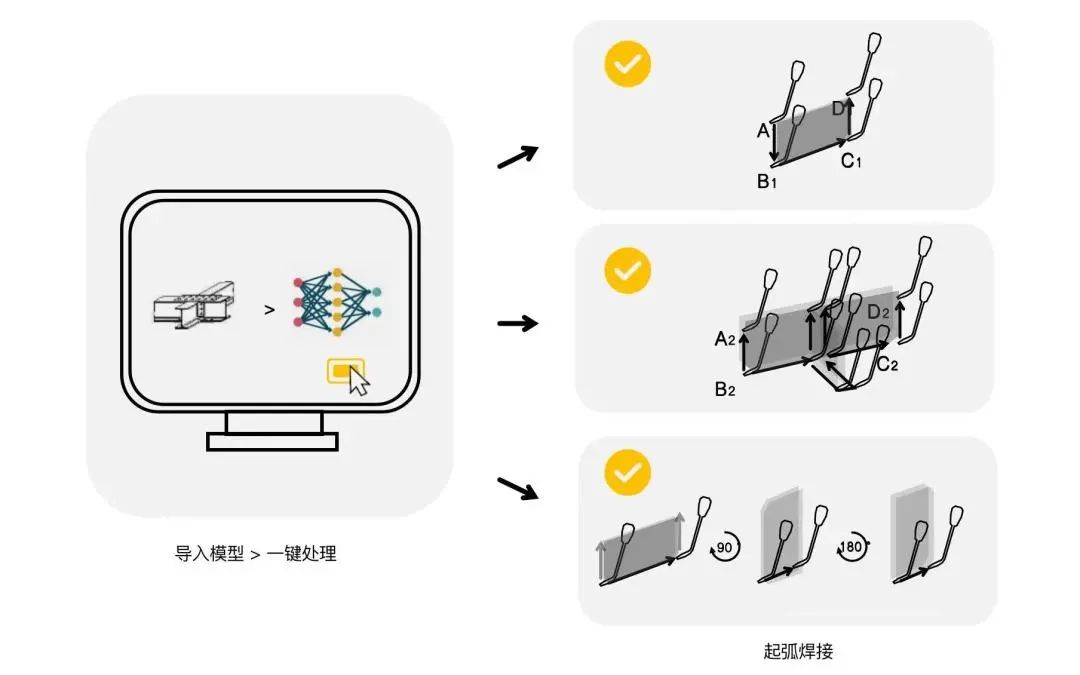

Our system integrates advanced algorithms for swift steel structure analysis and precise weld seam positioning, automating welding path generation to boost efficiency.

2.Laser Vision Algorithms for Precision

Our algorithms quickly scan workpieces, analyze weld seam positions, and autonomously address deviations for precision in challenging environments.

3.Intelligent Welding Expert Library

Covering various welding applications, our expert library recommends optimal configurations for enhanced quality and efficiency.

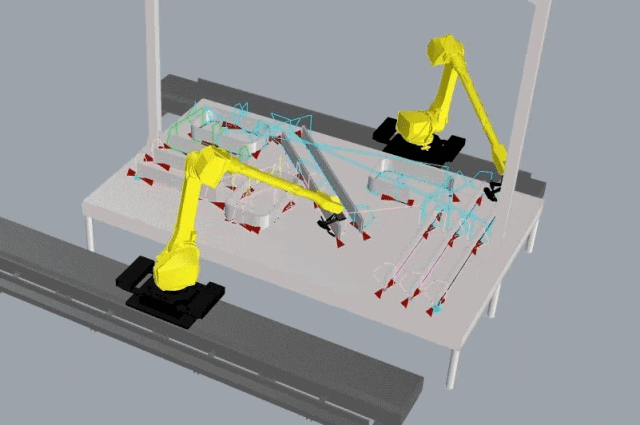

4.Multi-Machine Cooperative Robot Control

Our algorithm enables seamless collaboration between robots, components, and environments, enhancing efficiency and safety with intelligent trajectory planning and collision detection.

Teaming up with AluHouse, we've developed an efficient welding production line for the assembled steel building market in the Guangdong-Hong Kong-Macao Greater Bay Area. This solution integrates automated welding robots, flexible tooling, laser vision recognition systems, and RobimWeld software. It boosts efficiency, stabilizes quality, enhances safety, and reduces costs in actual projects.

Adopting this solution will drive technological progress and industrial upgrading in modular construction, injecting vitality into its future development.