News

cutting-edge technology

China Construction Railway Investment & Construction Group Co., Ltd (CCRIC), a subsidiary of China State Construction Corporation (CSC), stands at No. 9 among the world's top 500 companies. As a primary platform for China Construction's railway, urban rail, and infrastructure projects, CCRIC spearheads innovation in construction technology.

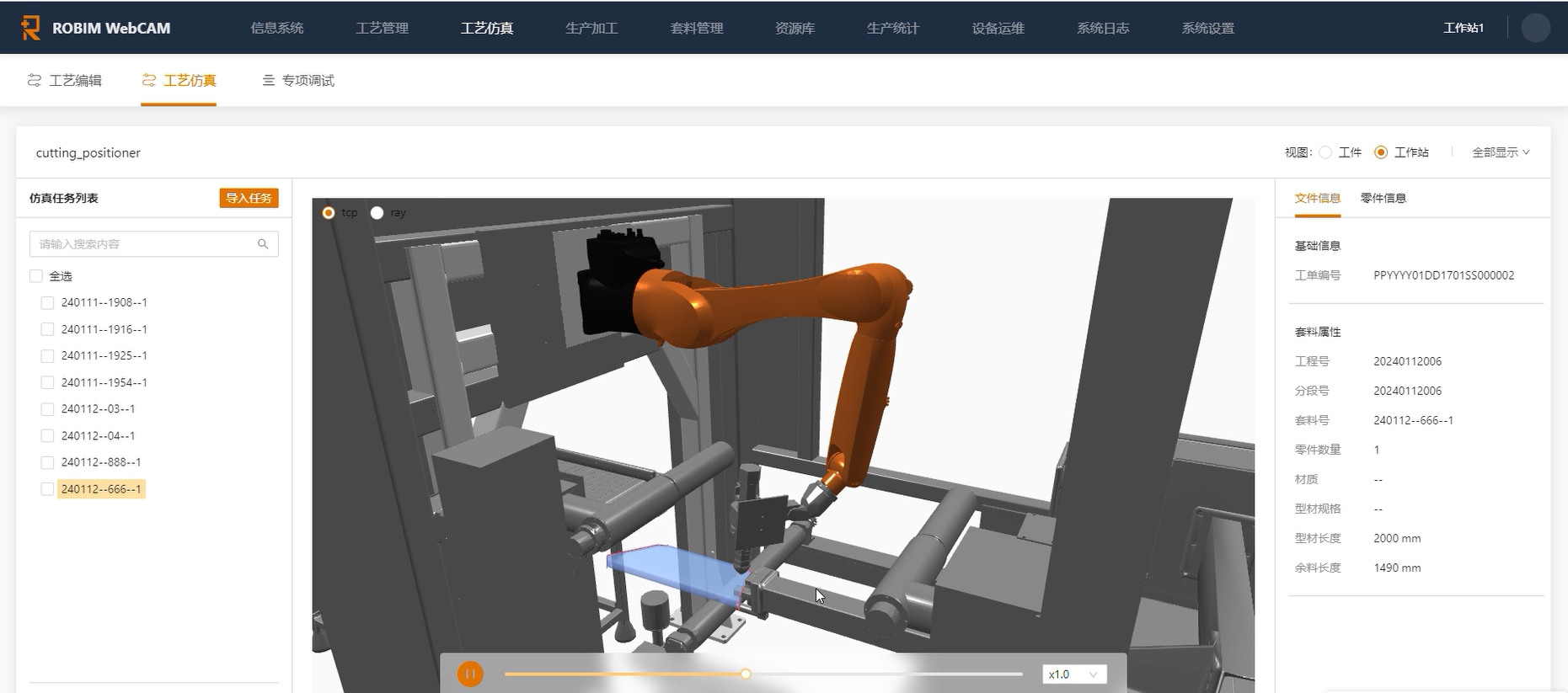

In collaboration with RoboticPlus.AI, CCRIC has unveiled an unprecedented advancement in steel processing – an intelligent rebar bending robot production line. Departing from traditional manual operation, this cutting-edge system leverages six-axis robots and RobimBend software to achieve fully automated workflows, from material loading to bending and sorting.

This groundbreaking production line boasts exceptional flexibility, intelligence, adaptability, and stability. It marks a first in China for comprehensive rebar bending, backed by three invention patents, four utility model patents, and two software copyrights. Its successful deployment on the Wuyi section of the Shanghai-Chongqing-Rongshan high-speed railway underscores its transformative impact on construction efficiency and automation.

Technical Advantages

1. Component Management

Tailored components for various steel shapes, supporting multi-species, small-batch production.

2. Material List Management

Seamless import of Excel bill of material files and manual creation.

3. Nesting Management

Optimized rebar reinforcement component nesting algorithm for enhanced material utilization.

4. Production Execution

Task-based bending with one-key operation, enabling unattended 24-hour production.

5. Capacity Statistics:

Comprehensive data collection and visualization for production analysis and reporting.